Download PDF Data Sheet

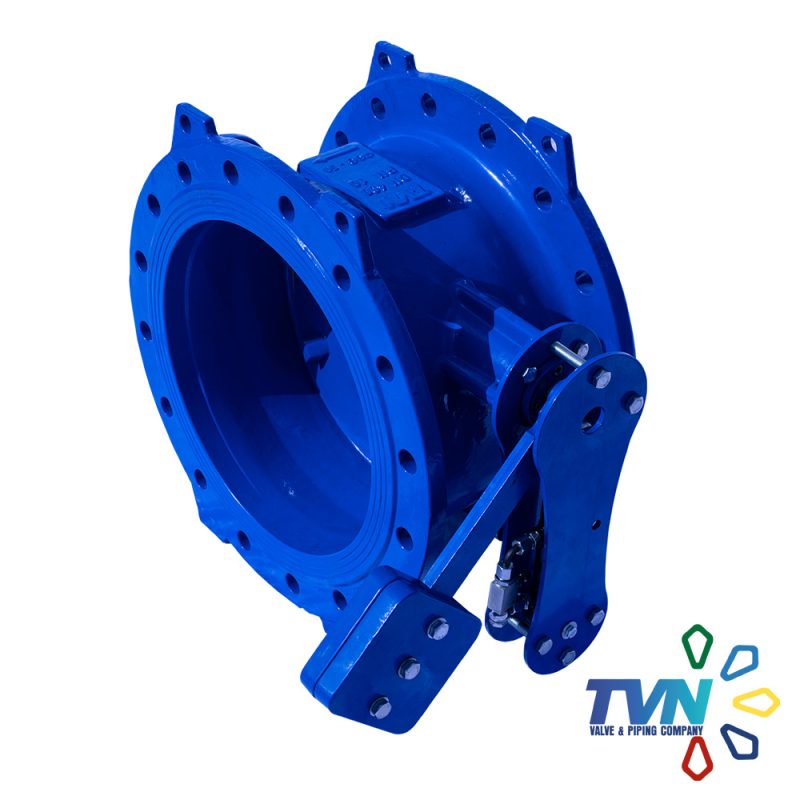

TVN V210 Nozzle Type Check Valve is used in applications where the reverse flow of a fluid has to be avoided. These valves are suitable for all kind of liquid and gaseous fluid and are safe by design. Lightweight discs and spring assisted closure combine to allow the Nozzle Check Valve to maintain the same high performance regardless of vertical or horizontal installation.

Application Range

- Water & hot water systems

- Steam applications

- Reservoir Lakes

- Suction Lines

Related Products

- V106 Double Eccentric Butterfly Valve

- V151 Gate Valve

- V852 Basket Strainer

- V251 Dismantling Joint

Nozzle Type Check Valve Product Features

- Nozzle check valves with bodies notably larger in diameter than their inlets display the best flow characteristics.

- The disc faces for all of our nozzle check valves are designed to maximize hydrodynamic efficiency and minimize pressure loss.

- All nozzle check valves from TVN, feature soft seat, a specially designed and sourced O-ring installed in the seat of the valve. Soft seat drastically reduces reverse flow leakage and aids the quiet closing of the valve.

- TVN nozzle check valves use only one spring designed for a million cycle life time in the body, as opposed to most other companies, which use multiple springs. Minimizing the number of springs reduces the potential for failure.

- Long service life, with minimum level of maintenance requirement.

- Suitable for horizontal and vertical installations.

- Minimizes water hammer e ffect in system

- Directional application, please check the arrow mark on the body for correct direction

- Flange connections according to EN1092-2 / ISO 7005-2.

- Hydrostatic test pressure for seat: PN x 1.1 (e.g.: PN 16 = 17.6 bar); for shell: PN x 1.5 (e.g.: PN16 = 24 bar) according to EN 12266-1.