Download PDF Data Sheet

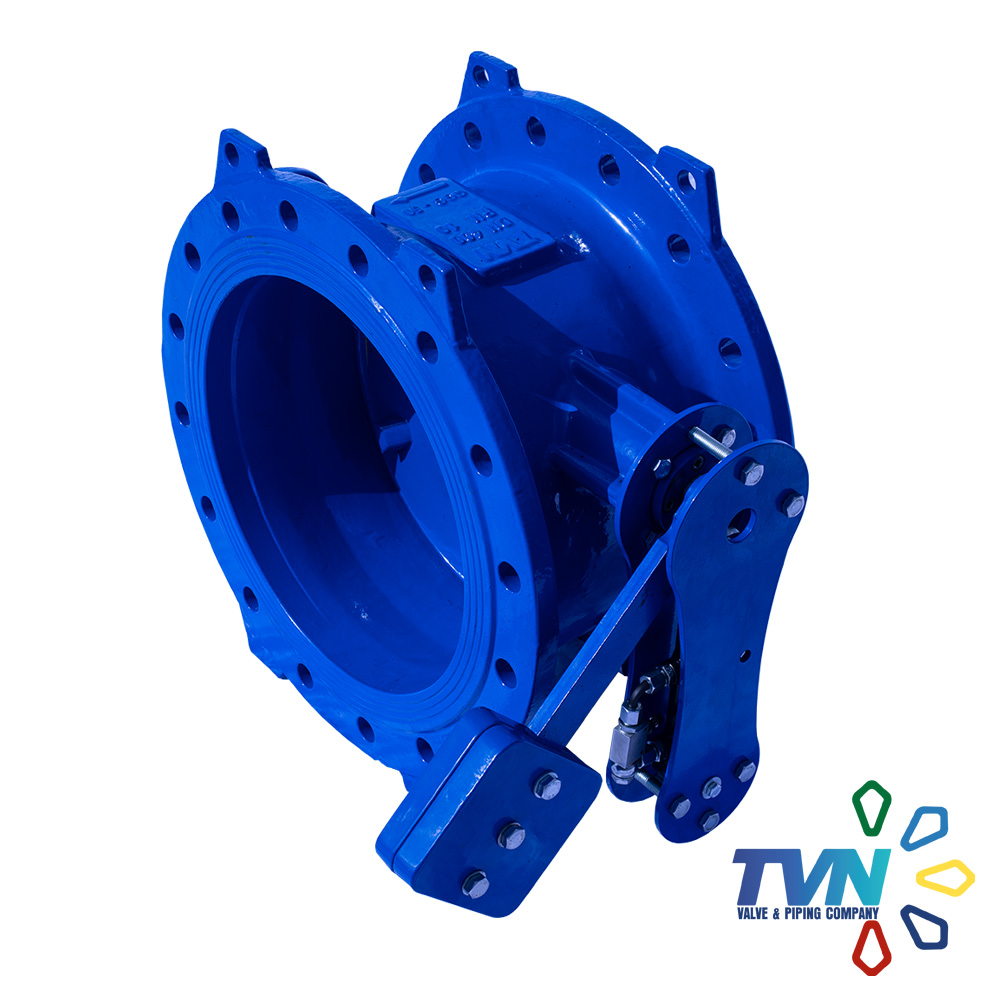

TVN V203 Hydraulic Tilting Check Valve is the non-return valve preferred in pipe networks where faster closure is required and water hammer affects needs to be absorbed. Through the counter lever and weight attached to its shaft via the hydraulic piston, ensures a soft open depending on the speed of the flow and maintains reduced closing times when flow stops.

With its disc design where the center is shifted in two axis, this leads to a big improvement on decreasing operation torque values, lowering the friction on disc sealing area and extended service life.

Application Range

- Pumping Stations

- Water Transmission Lines

- Tanks

- Water Treatment Plants

- PowerStation Cooling Lines

Related Products

- V106 Double Eccentric Butterfly Valve

- V151 Resilient Seated Gate Valve

- V251 Dismantling Joint

Hydraulic Tilting Check Valve Product Features

- GGG40/50 Ductile Iron Body & Disc allows high impact and stretching resistance

- Double Eccentric / Double Offset Disc Design

- Resilient Seated Type (Metal seated type optional)

- Disc sealing ring EPDM as default. NBR or VITON options are available

- Block molded solid/one-piece T-shaped disc sealing ring extends drop-tight sealing life time

- The open/close speed can be adjusted by opening and closing the valve located on the hydraulic piston.

- Counter Lever & Weight position can be replaced on both sides. Two counter lever option is also available upon request.

- Possible to install on horizontal and vertical pipelines with varied flow directions. It is necessary to mention the lever positioning requirements according to your project in order to arrange the lever side and position during production.

- Easy to replace disc sealing ring without dismantling the valve from the pipeline and without dismantling the disc from the valve itself just by taking out the retaining ring through its bolts. It is easy to replace the disc sealing ring without any additional equipment’s

- SS308/316 grade stainless steel welding seat on the body is manufactured through automatic welding machines and microfinished precise milling operation. When disc is fully closed, disc sealing ring applies equal pressure on every point on the welding seat.

- Drop-tight closure

- Triple O-ring feature on both shafts ensures high sealing

- Shafts are equipped with bronze bushings having high corrosion resistance

- Ensures minimized pressure loss and increased energy efficiency with double shaft design

- Low torque requirements during operation

- Easy to install on the line, light weight and occupies less space

- Full coating on the body and disc internally & externally with an average of 250 microns. Higher coating thicknesses are available when required.

- WRAS approved coating available upon request which meets hygienic requirements for potable water applications • Maintenance free design

- For proper installation, direction arrow on the body should be considered.

- Balanced positioned lifting holes on the body ease transportation and installation

- Hydrostatic test pressure for seat: PN x 1.1 , for shell: PN x 1.5 according to EN 12266-1.